Mold design and molding of plastic materials

4C Srl is a company equipped with experts and professionals in the design and construction of molds and molding of plastic materials. Over the years we have always invested in new technologies, today managing to design and produce reliable, quality items in the most popular sizes and weights.

Services

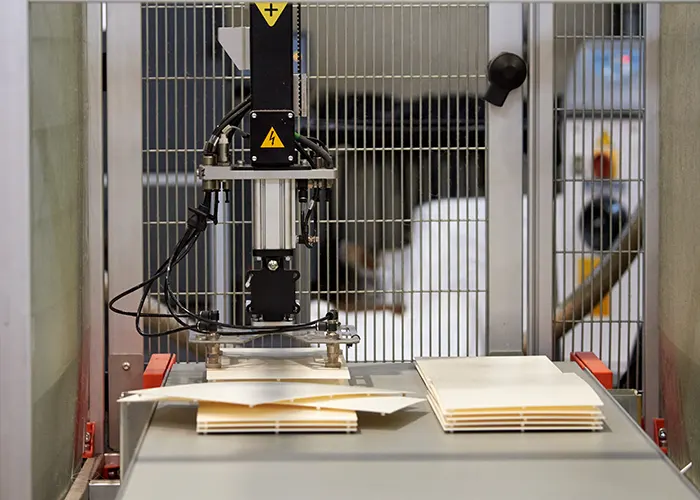

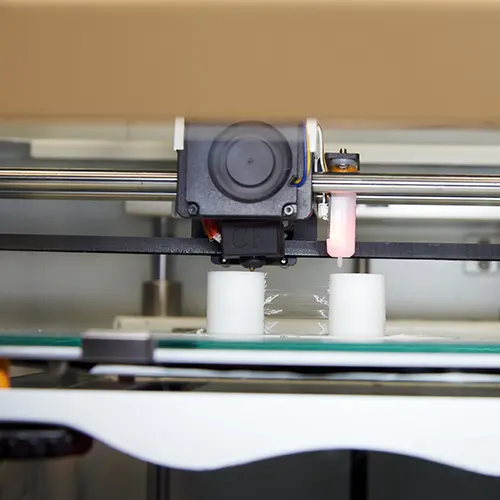

PROTOTYPING AND MOLD DESIGN

Through the rapid prototyping service on measurement and planning is possible work on the product so as to suggest solutions that optimize the product and its related engineering.

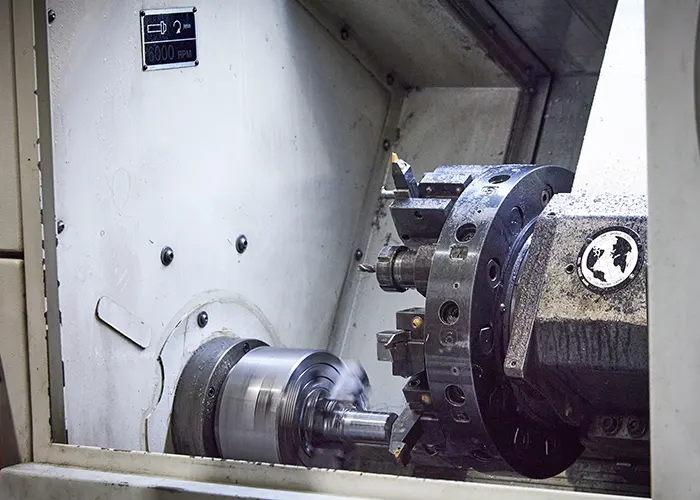

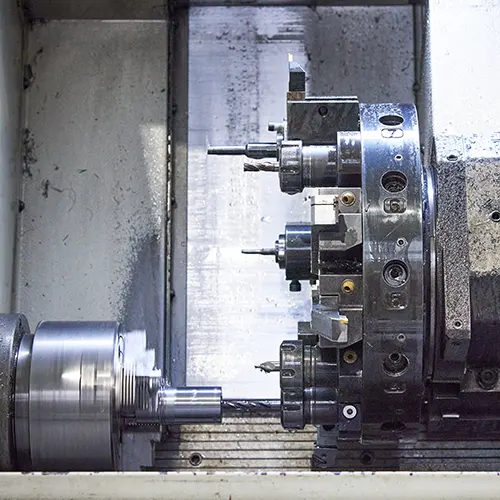

MOLD CREATION

After the design, the project is transformed into a mould, molds that are efficient to production requests are created through numerically controlled machining centres.

PRINTING

Technopolymer and rubber injection molding center equipped for quality production.

What are we characterized by?

COMPETENCE

FOR 3 GENERATIONS

We carefully analyze both the product to be printed and the entire production process of your company, and identify the most effective technology to maximize your productivity.

AESTHETICS AND FUNCTIONALITY

The cutting-edge equipment and our ability to use them to the fullest guarantee the optimal balance between functionality and aesthetic performance of your product.

SERVICE

At 360°

We accompany you "from your desk to your customer", supporting you in the complete industrialization of your product and providing welding, finishing, assembly and logistics services.

SUPPORT

BUSINESS SUIT

With us you are never alone! Our response times are very short, and we guarantee maximum delivery flexibility, also making the warehouse service available to you.

Merchandise sectors

We have been specialized for more than 30 years in the creation of molds and molding for many product sectors.

We are always looking for the possibility of exploring even areas not treated or treated marginally with our services.

4C Srl does not exclude any experience, every new professional collaboration in the virgin sector can be the input of a new functional project.

We have particular experience in the following sectors:

indoor&outdoor furniture, electronics, water and coffee dispensers and purifiers, awnings, pergolas and micro and macro appliances.

How we work

4C Srl uses a 5-phase production process:

We listen to our customer to understand his needs and we walk the road towards the project together.

We create a prototype in collaboration to optimize the product before even creating it.

Let's move on to the stage of creating the material mold.

We proceed to create the client's initial project.

We deal with ancillary services such as ultrasonic welding, finishing and surface treatments but also assembly, packaging, logistics and transport of your product

What our customers say about us

News

The technical skills that are the basis of your product's success

Furniture sector: 4C Srl guide to rapid prototyping

The ideal partner in prototyping and production for Startups

The injection molding process

The MOCA Certification

4C srl and the ISO 9001 Certification

Need more information?

Do you have a mold and stamping project in mind and don't know how to make it and who to entrust to? Contact us, we are able to provide you with the most suitable solutions and process for your project!