Materials for production

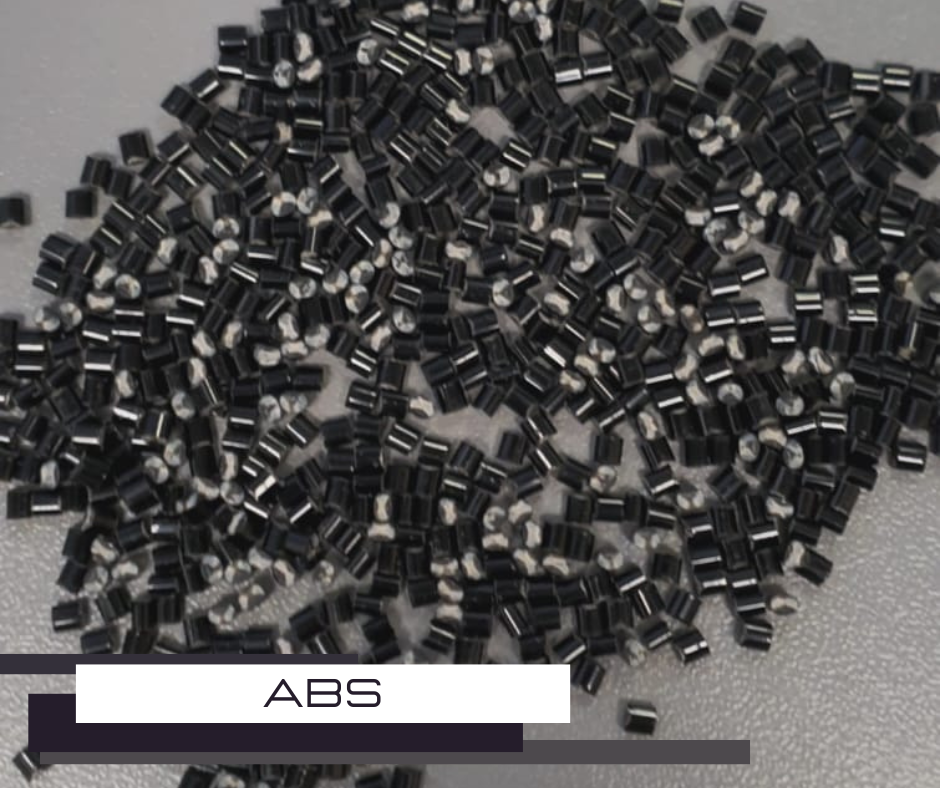

polymers

The plastic it is a macromolecular material formed by polymers of different lengths. It is created in the laboratory.

In detail: polymers are formed through the union of various monomers, the latter compounds of carbon and hydrogen in turn deriving from petroleum and methane. The polymers together, therefore, form a single linear molecule, namely the plastic. Other substances are then added in order to give the material the desired characteristics. Ultimately, we can say that plastic is obtained with the chemical processing of petroleum to which other elements such as coal, cellulose and natural gas are added.

There are many types of plastics but the great subdivision is given by their reaction to contact with heat. So we have thermoplastics, i.e. those plastics which soften when they come into contact with high temperatures and which can be infinitely moulded, and thermosetting plastics which, on the other hand, can no longer be moulded, once they have melted and become rigid again.

The 4C Srl company uses polymers for the production of moulds, injection moulds, industrial and customized moulds.

Eraser

Another material widely used by 4C Srl Mold design, it's rubber. It is a material that has a particular quality: thehigh elasticity. This means that the rubber can deform under the action of an external force and then return to its original shape when this force ceases.

There are two types of tires: natural and synthetic.

There natural gums they are obtained through the coagulation of the latex obtained from some tropical plants. They have high mechanical characteristics but little resistance to atmospheric agents and temperatures.

The synthetic rubbers they are obtained starting from simple hydrocarbons which generate, through polymerization, artificial latexes which are then coagulated. They have very different mechanical and chemical resistance characteristics.

TPUs

The thermoplastic polyurethane (TPU) it is a polymer that comes to itself form from the polycondensation of an isocyanate with a god. The resulting material, based on the chemical nature, can be similar to natural rubber or to a plastic type material with permanent deformation. Thermoplastic polyurethane is a substance with high resistance to oils and abrasion. Plus it is impermeable to water and gas. On the other hand, it has poor resistance to acids and bases and requires additives to be able to resist UV rays.

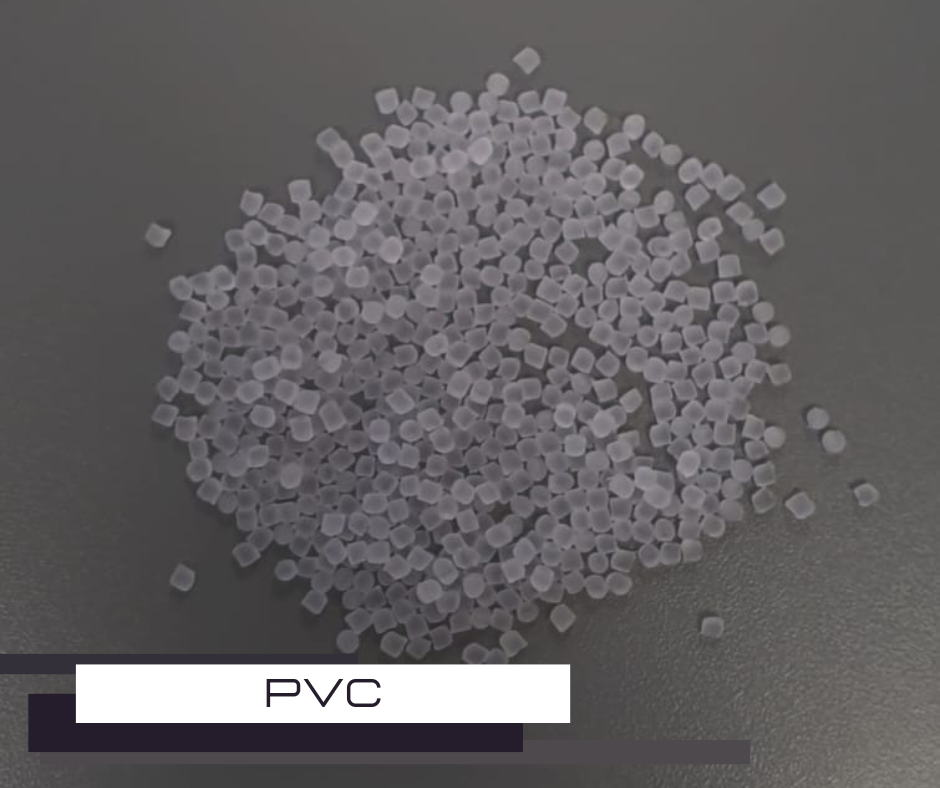

PVC

PVC is a thermoplastic material which derives from raw materials of natural origin. It is occurs naturally in the form of a white powder which, linked to specific polymers mixed with appropriate tools, allows you to create a very malleable material.

It adapts very easily to any situation as, among its own main features, we find the solidity and resistance, in addition to flexibility. It is also a recyclable and eco-friendly material.

The PVC it is part of the thermoplastic materials but, unlike plastic, it has a high degree of elasticity and fire resistance. It does not stain, does not absorb liquids and has a very long duration over time.

For these extremely positive characteristics, PVC is a material widely used in suitable production processes.

The company 4C Srlspecifically, it uses PVC in the industrial cycle of the product and for moulding.