Today we will tell you how one of the most important phases is managed within 4C Srl concerning the storage of raw materials through a transportation and distribution facility.

If the "fuel" is for us the raw material, the entire transport and distribution system is the "engine" that drives our final production.

Let's try to imagine together what happens when we buy a one kilo pack of pasta. Once home, the package is cut and placed in a convenient container; every time I want to cook myself a portion I'll have to take the scale, weigh 100 grams of product and put away its container.

These are mechanisms that we carry out autonomously every day at most once or twice a day, but we must try to imagine having to repeat these operations over and over again during the day ... it would become very expensive in terms of time, energy and effort.

At 4C Srl we have optimized our systems significantly reducing the work space, moving containers, dryers and dehumidifiers to an adjacent warehouse in order to also lower the enormous heat dispersion, thus creating a more livable and manageable work environment by our staff.

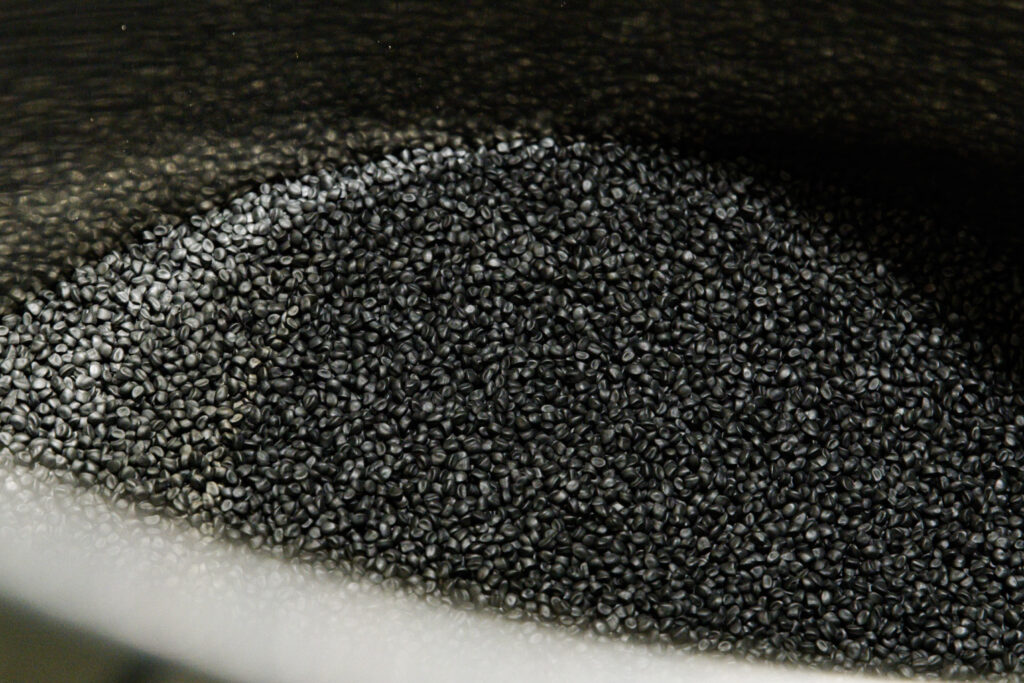

The bags of raw material are no longer loaded manually by our operators, but the material inside the containers is mechanically stored autonomously.

Through a software the operator will be able to establish some values among which quantities and temperatures and the raw material will be conveyed through air pipes under pressure inside the press. In this way the material will not undergo any variation in humidity and not coming into contact with external agents will keep its qualities unaltered.

And as for pasta, tomato sauce will be added at the end of cooking, also for the final part of the process just described to the raw material some dye will be mixed (master), with percentages already pre-established by the software and on an ongoing basis.

We have tried to summarize in a few words what is one of the most important mechanisms of 4C Srl, a state-of-the-art process which guarantees us one increasingly continuous and linear production, eliminating the possible risk of introducing micro dust into the air. A further step in favor of the environment and our company.